Reinforced concrete is a type of concrete used in industrial construction in a very recurrent way. It is characterized by having a series of reinforcements that make it stronger and more flexible.

What is reinforced concrete?

El hormigón armado hace referencia a un hormigón reforzado con una armadura de mallas o barras de acero.

Se trata por tanto de un material al que se le han añadido unos refuerzos metálicos de acero para obtener un tipo de hormigón que soporte una alta resistencia a la tracción.

Tenemos por un lado, al hormigón, el cual es un material resistente a la compresión pero que no lo hace bien frente a la tracción. Y por otro lado, al acero, que ofrece buena resistencia a la tracción y a la compresión.

Con la unión de ambos materiales obtenemos como resultado al hormigón armado, un material mucho más resistente a la compresión y tracción.

Gracias a estas características, el hormigón armado es usado para la construcción de estructuras y cimientos: edificios, puentes, túneles, y obras industriales en general.

Es un hormigón que puede ser construido in situ, como en una fábrica cuando las condiciones lo permiten.

Es también habitual usar junto al mallado de acero, fibras de vidrio o plásticas, logrando así una unión de fibras y barras que lo hace aun más resistente.

In civil construction, the use of fibers is usually applied by shotcrete.

Historia

It was invented in France by Joseph-Louis Lambot. In 1848 he built the first reinforced concrete ship, which is kept in the Brignoles museum.

Reinforced concrete continued to develop with François Coignet. He had the idea of using it on ceilings, pipes, vaults, and walls.

The first to use it in Spain was the military engineer Francesc Macià with the design of the Puigverd water tank. The first important building to be constructed in Spain, using reinforced concrete, in the “Las Ceres” flour factory in Bilbao from 1889-1900.

Reinforced concrete components

The composition of reinforced concrete consists of portland cement (usually), water, aggregates of silica sand or gravel, and steel bars, meshes, or synthetic steel fibers.

Characteristics of reinforced concrete

This type of construction material represents an improvement over regular concrete.

Advantages of reinforced concrete

The advantages of using reinforced concrete are the following:

- The materials used are always available and affordable.

- It needs very little maintenance and is very durable.

- It allows molding and adjusting to any architectural need.

- It weighs a lot and has a large volume.

- It has anti-seismic properties.

- It resists very well to pressure and traction of forces.

Uses of reinforced concrete

Reinforced concrete is used in all kinds of constructions and buildings. Some of which are the following:

- Concrete floors, for grounds that are going to support a heavyweight, such as the passage of vehicles.

- Foundations for building structures. All foundations for buildings, in general, are made from reinforced concrete in order to provide greater stability to the construction that will be built on top.

- Rooftops: for these cases, 4mm electro-welded mesh with lightweight concrete is used.

- Floor slabs, to differentiate and withstand weight between floors. The formwork uses underpinned iron plates that are filled with reinforced concrete.

- Concrete ring beams, filling the trenches where the concrete and steel will be placed.

Why use reinforced concrete in construction?

Reinforced concrete already has all the advantages of regular concrete, that is, it is a moldable construction material, which can be used anywhere to fill voids, make foundations or structures, has adherent properties and once hardness, it can withstand against pressure and weight.

If we add steel bars, meshes, or synthetic fibers, it is possible to increase its strength furthermore and improve its flexural strength. That is the reason why reinforced concrete is always used to create complex foundations or structures.

By adding steel to the concrete, ductility is incorporated. This property allows the reinforced concrete when subjected to force, to deform without breaking.

This ductility enables the concrete, for example, used for foundations to support the weight of buildings on top. If it were not so, the weight it would bear would not allow a compression effect and derived tensions from the construction on top, causing the building to collapse.

How to make reinforced concrete for floors

The usual dosage using rounded river aggregates is the following:

- Cement: 300 – 350 kg.

- Gravel: 800 – 900 kg.

- Sand: 400 – 500 kg.

- Water: 200 liters.

The 5 steps to make reinforced concrete for floors are:

1st Excavation

Depending on how rugged or uneven the terrain is, it may be necessary to carry out an excavation task.

When it comes to clay soils, building a trench with compacted rubble is sometimes necessary. A ditch that surrounds the perimeter of the planned construction layout.

2nd Drainage

All wet areas in the ground must be removed. If this isn´t carried out, it could lead to future subsidence in these areas. For drainage, usually, a French drainage pipe is used, useful to extract still water in complicated areas.

The usual thing is to cover the soil with a layer of crushed stone and a geotextile to avoid the accumulation of sediments.

3rd Filling

The filling consists of spreading a permeable filling material. Vibratory computers are often used for this task.

4th Compaction

Compaction is an obligatory step in all soils since it will be the base that will support the reinforced concrete floor.

Its durability will depend on the compaction, which will offer resistance by increasing the contact between the granular material, expelling the air.

5th Formwork

El encofrado es un sistema de moldes que se utilizan para verter hormigón y darle la forma deseada antes del fraguado.

This system allows temporary or permanent moulds, which can be metal or wood nailed to the ground and with a rope line tied at a right angle.

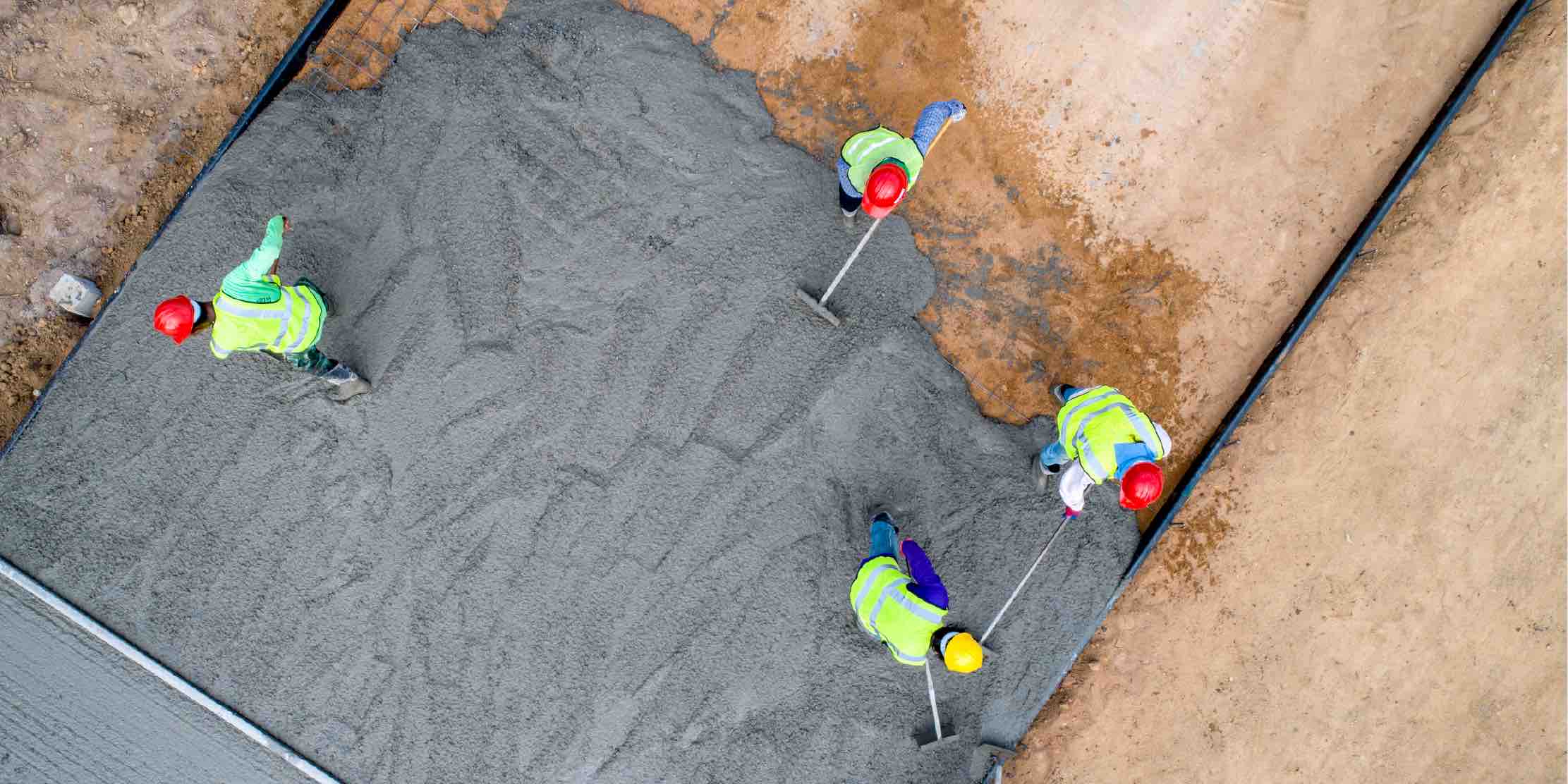

Inside the formwork, the steel mesh reinforcement or beams are placed and the concrete is poured into.

Cómo mejorar este suelo aun más

Un suelo de hormigón armado puede ser mejorado con un tratamiento de hormigón pulido. Este tratamiento aumentará aun más ciertas ventajas del armado y ofrecerá nuevas cualidades.

Con dicho tratamiento se aumentará la resistencia, la durabilidad del pavimento y lo hará antipolvo. El mantenimiento de dicho pavimento será reducido y su limpieza más fácil. Aumentará su dureza permitiendo el paso de maquinaria pesada, impactos y abrasiones y aumentará el ahorro energético por la reflectividad de este suelo.