Improve your industrial floors with our planimetry and levelling service, which ranges from an initial assessment of the existing planimetry and levelling to the implementation of improvements to achieve the desired planimetry and levelling, followed by our BECOSAN® treatment to maximise the durability and functionality of the floor.

The high-end BECOSAN® planimetry and levelling service follows a structured process to ensure accurate and efficient results on every project:

Initial analysis to determine the quality, flatness and current level of the ground.

Implementing technical improvements to achieve optimum levels of flatness and precision.

Final application of our specialised treatment for polished concrete to improve the durability and strength of the floor.

BECOSAN® high-gloss industrial floors with BECOSAN® finish comply with standards, offer maximum safety and are absolutely practical for any industrial task requiring extreme flooring.

Carrying out projects with millimetre precision is crucial for installations requiring very tight tolerances, such as high-precision machines or automated warehouses.

A very level floor reduces the risk of accidents caused by uneven ground, which helps to make the working environment safer for staff and for driving commercial vehicles.

Ensuring that facilities comply with quality and safety regulations and standards to avoid penalties and improve the company’s image.

Our flooring improves the efficient use of automation equipment such as AGVs, LGVs, AMRs, VNA forklifts and AutoStore systems. This minimises wear and tear, reduces maintenance and avoids risks such as load shifting, falls or collisions.

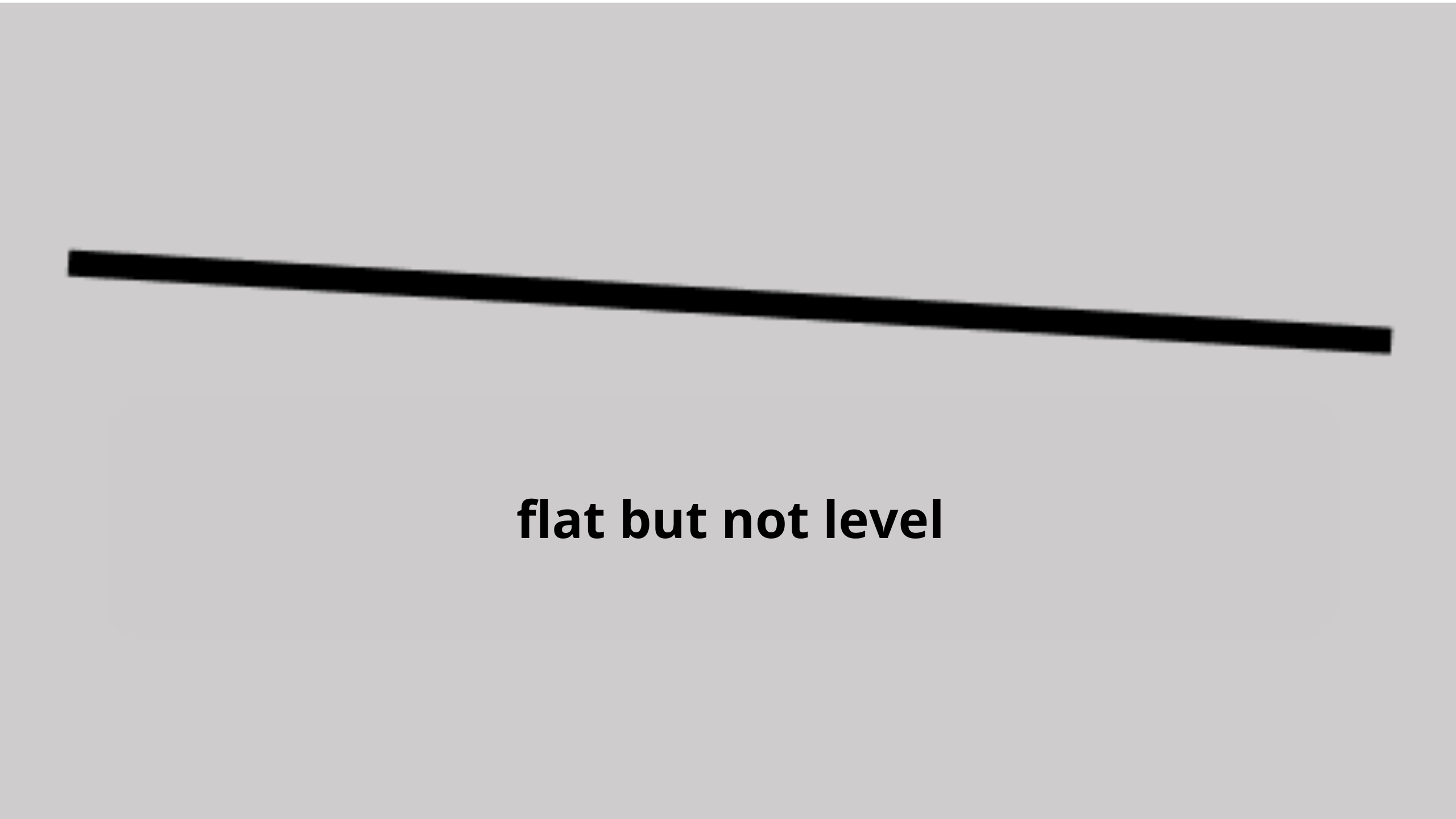

High levelling focuses on creation of extremely flat and uniform surfaces, which are essential for supporting and ensuring the efficient operation of advanced machinery and automated systems in industrial environments. This service uses advanced techniques and cutting-edge technology to measure and correct floor imperfections to ensure exceptional flatness to the most exacting specifications. It is ideal for sectors such as logistics and manufacturing, as well as areas where rigorous control of ground conditions is required for the installation of sensitive equipment or to facilitate the passage of automated vehicles.

We improve industrial surfaces by ensuring that they are as flat as possible, using cutting-edge technology to guarantee the uniformity required by precision machinery and automated systems.

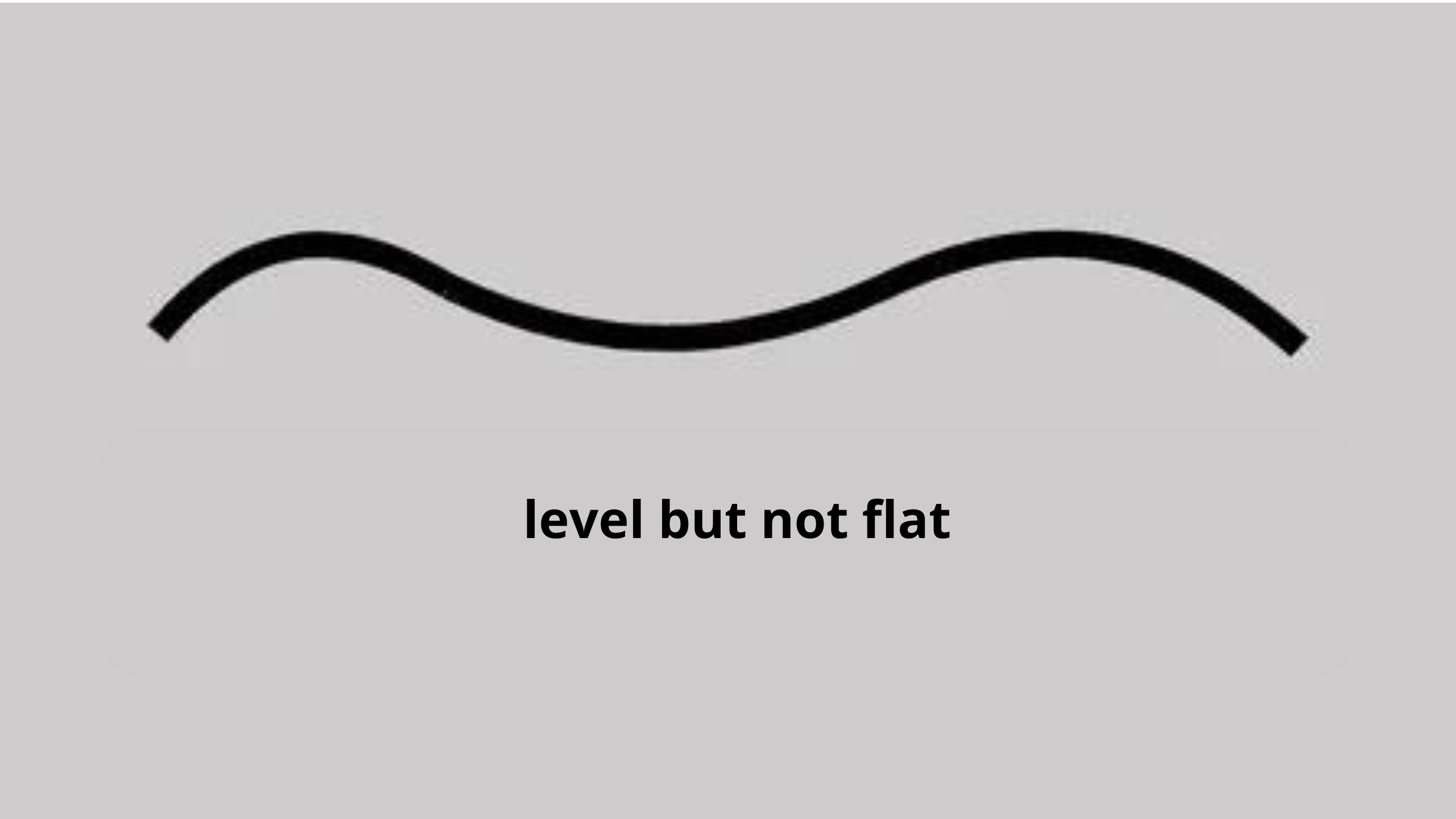

Levelling involves adjusting the ground surface so that it is completely horizontal or follows a specific slope to facilitate drainage or meet other design requirements. Our approach combines detailed assessments with cutting-edge technologies, such as the use of lasers and GPS, to identify and correct deviations from the desired slope. This step is crucial not only to ensure the functionality and safety of the installation but also to prevent long-term problems with water run-off, structural stability and pavement integrity.

We adjust the ground to the desired level, using precise techniques to correct slopes, which is vital for the safety and functionality of the installations.

We begin our planimetry and levelling service with a thorough preliminary analysis, using state-of-the-art technology to accurately assess the flatness and level of the ground in order to identify possible improvements.

This essential step enables us to gain an in-depth understanding of the current situation on the ground, uncovering any irregularities or deviations and their impact on the functionality and safety of the area. This initial diagnosis is essential for designing a tailor-made action plan to effectively meet the needs of the project.

Once the preliminary analysis is complete, we move on to the high-level planimetry and levelling adjustments stage. This stage focuses on implementing advanced technical improvements to correct any irregularities found and raise soil quality to optimum levels. Using state-of-the-art equipment and precise levelling techniques, we can adjust and improve the flatness and horizontality of the ground with millimetre-level accuracy.

This phase is essential to ensure that the ground meets the highest quality and safety standards, making it easier to carry out industrial and commercial activities with maximum efficiency and reducing the risk of incidents related to ground quality.

The final step in our process is the application of BECOSAN® polished concrete treatment, a specialist solution designed to maximise the durability and strength of the floor.

This treatment not only improves the aesthetic quality of the floor, but also protects it from wear, dust and other factors that can compromise its longevity and functionality. Applying the BECOSAN® polished concrete treatment results in a smooth, densified and sealed surface that is robust and easy to maintain.

This phase completes the planimetric and levelling process, providing a top-quality industrial floor that is ready to face day-to-day operational challenges and significantly extend its lifespan.

Here are some answers to the most frequently asked questions about our high-level floor levelling and industrial building levelling services in France.

Absolutely, our service is designed not only for new construction projects but also to correct and improve existing floors with flatness and levelling problems.

Accurate planimetry and levelling of industrial pavements are essential for the smooth operation of machinery and automated vehicles, minimising the risk of accidents and improving the durability and maintenance of the ground.

We use state-of-the-art technology, such as laser scanning and digital levels, to accurately measure the flatness and horizontality of the ground, enabling us to identify any irregularities that need correcting.

Our service complies with the most stringent international regulations and standards in terms of the quality and safety of industrial floors and is tailored to the specific needs of each sector.

We offer a wide range of specialist technical tests to complement our flatness and levelling offer, providing a complete solution for the maintenance and improvement of industrial floors.

We carry out grip assessments to identify potential hazards and contribute to a safer working environment by evaluating ground grip.

Our abrasion tests measure the resistance of floors to wear and tear from continuous use, providing a key diagnostic of their durability.

These tests enable us to assess your floors’ resistance to impact and pressure, which is essential for determining their load-bearing capacity and strength.

The gloss test is used to assess the aesthetic appearance of floors and to determine whether they comply with workspace standards.

These tests determine the surface texture of your floors, which is crucial for safety by improving grip and preventing slipping.

We identify the level of moisture in your soils to prevent long-term structural problems and ensure the integrity of the infrastructure.