Since the appearance of synthetic materials in construction, the technology regarding finishes has evolved rapidly, contributing in many ways to lowering costs.

The latest advance was driven by the fusion of both organic with synthetic materials, resulting in the origin of what we know as composite materials and the composite decking.

Wood-plastic composite is a type of flooring that proves the technological potential that has yet to reach the construction sector.

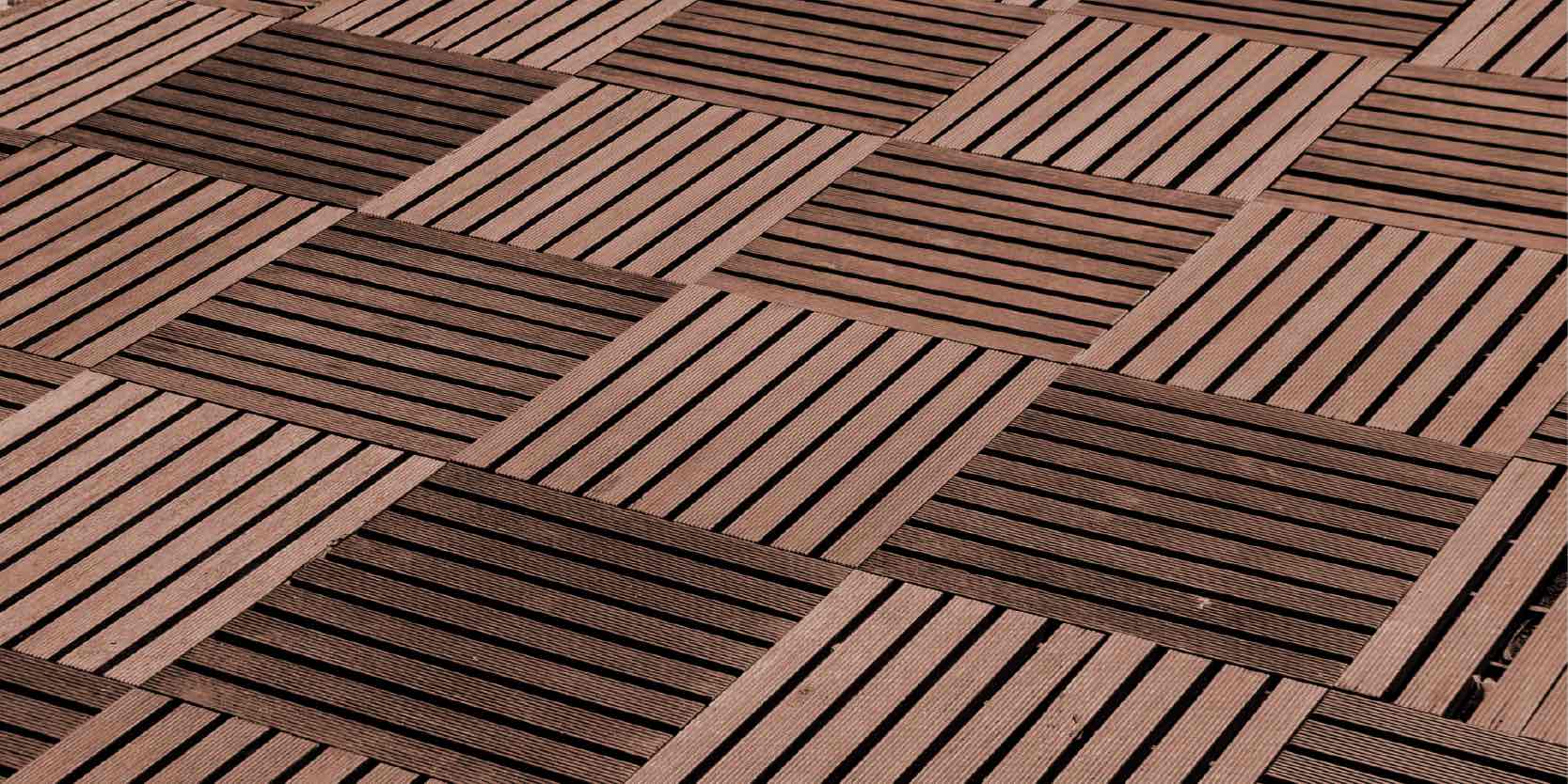

Currently, it is in high demand for outdoor use due to its elegant appearance which is identical to wood. However, there are a few technical aspects that should be mentioned about this material, this is why we have prepared this post.

Wood-plastic composite floor

Composite flooring is also known as wood-plastic composites (WPC).

This composite flooring is produced by thermal processes that restructure the polymer’s composition, using temperatures above melting point to mix the required elements.

The most commonly used polymers are polyvinylchloride, polyethylene, polypropylene, and polyurethane. These are mixed with wood fibres, in a proportion that varies between 50 to 80%, to obtain the composite floor. Industrial lubricants, fire retardants, UV stabilizers, and pigments are usually added to the mix.

Most of the mentioned components are recycled, so we are talking about product that has a low environmental impact, being highly sustainable.

Composite floor manufacturing processes vary, but the most common process is extrusion, which establishes the characteristic shape of the composite deck board.

Main characteristics of a wood-plastic composite decking floor

Below we mention the most significant aspects regarding this material:

- It has less rigidity and resistance than wood. However, its slip resistance is superior.

- It is susceptible to deformation when large loads are applied and can experience structural alterations due to thermal changes; heat softens it and cold makes it brittle.

- It develops dimensional stability, so it doesn’t undulate and doesn’t absorb as much moisture as wood does.

- High resistance to microorganisms, such as fungi, xylophagous larvae, and termites.

- Similar installation process to wood.

- Recyclable material.

Uses of wood-plastic composite floor

Analyzing the characteristics and uses of a wood-plastic composite, we can conclude that it is a material that can have sufficient mechanical resistance when its thickness is increased.

On the other hand, to counteract the sudden thermal effects when using this synthetic wood, expansion joints are used.

This way some of the synthetic wood’s defects can be avoided.

However, it is convenient to dig a little deeper to know in detail if it is an appropriate option depending on each particular case.

Disadvantages of a wood-plastic composite

- Solar radiation causes the darkening of the decking boards.

- They can generate static electricity.

- They are susceptible to overheating, an occurrence that is accentuated depending on the color of the surface.

- Composite decking boards cannot be repaired. If they suffer serious damage, they must be replaced.

Where to use wood-plastic composite?

Once the advantages and disadvantages are known, it can be concluded that it is not a completely versatile material, and obtains worse results when compared to other floor coverings such as vinyl and linoleum floors.

However, when compared to wood, an organic-synthetic floor wins, since it is an improved version of the organic chemistry, making it a more resistant and durable alternative thanks to the structural configuration of its polymers.

Synthetic decking is mostly used for residential exteriors, mainly due to its sophisticated and elegant appearance, in addition to the maintenance being much easier compared to traditional wood planks.

In commercial and industrial buildings this flooring has practically no use, due to the high traffic conditions which are a limitation for the composite’s wear and load resistance.

How to install a composite deck

As we express in this article, composite flooring tends to be used in external environments, so we will specifically explain how to install a composite deck.

However, for interior installations, the differences are mainly based on environmental issues when placing the composite boards.

In basic terms the installation consists of 3 stages:

Placing the battens

This stage consists of laying thick synthetic wood battens, the height of which can be adjusted.

It is important to determine the orientation and leveling of the battens, to allow water drainage, no matter how low the battens may be.

Another significant aspect is the spacing between battens. Usually, these are separated by about 40 cm, but, if the traffic conditions are demanding, it is advisable to reduce the separation to 30 cm. There should be a slight separation between the ends of the strips, which is usually 15 mm.

Installing the boards

It is important to clarify that the first row of boards to be installed will be fixed differently to the rest. Also, expansion and contraction joints must be foreseen. When starting from a wall, a 1cm gap must be left.

The installation of composite floors consists of fixing the boards to each other by using decking clips, and screwing them to the batten system. The clips facilitate the preservation of the spacing between boards.

If the final space to be covered does not conform to the shape of the last board, the board must be cut. If this affects the decking clip slot arrangement, then adhesive or steel screws may be used to fix it to the batten.

Edging

Once the installation of the boards has been completed, for aesthetic reasons, perimeter covers are usually used. Although skirting boards can also be installed.

Some recommendations

- Let the synthetic boards rest for 48 hours, in a closed and flat place, without sunlight.

- The ideal temperature for installation ranges between 10 and 40 ° C.

- The batten system must be established on a flat and stable surface.

- The battens must be inclined according to the maximum slope orientation.

What is the maintenance of a composite floor?

The maintenance of a composite flooring is one of the greatest benefits of this synthetic material since it is an extremely simple and cheap material compared to the care that wood requires. The simplicity of its maintenance is similar to a PVC floor.

The main problem with organic-synthetic floors is their sensitivity to solar radiation, which causes the appearance of stains on the surface. However, there are some types of composite floors that solve this problem. Stains can be removed by using conventional cleaning products.

Cleaning these floors can be both dry and wet. It is recommended that dry cleaning to be weekly, while deep wet cleaning to be annual.

An important maintenance detail is that if it is seriously damaged it cannot be repaired, and must be replaced. In the case of scratches or superficial burns, some technicians and manufacturers recommend using fine-grit sandpaper, but this can affect the surface aesthetics.

We offer concrete polishing services in the UK and Europe.

10 years dust proof guarantee. Unique BECOSAN® patent