Managing an industrial facility is a crucial task and is the main way to make production activities run efficiently.

Industrial management uses various techniques, as well as the knowledge and innovation of professionals to optimize productivity and order in a facility.

An industrial facility cannot exist without management, as it would become a non-productive chaos that would gradually ruin the whole industry.

Why is an industrial facility management so important?

First of all, industrial management is important because it allows efforts, skills, and resources to be directed towards productivity and efficiency.

Industrial management is composed of a wide set of techniques that seek to minimize time, costs and losses, in order to increase the value of production.

Although management is generally associated with the industrial facility production, the truth is it also covers processes such as storing, organizing and distribution, all of which are activities closely associated to production.

It should be noted that management is useful for planning and scheduling industrial building renovations (and/or maintenance) so as not to interrupt or affect production activities.

Who is in charge of managing industrial spaces?

In production, industrial engineer are the main managers, since they have the knowledge, experience and professional training to apply the techniques correctly.

An industrial engineer is familiar with production processes. This is a professional trained to carry out industrial optimization.

However, it’s generally the managing directors who are in charge of managing an industrial facility.

A manager has to organize, plan and control activities additional to production, such as storing, distribution, etc.

Techniques to efficiently manage a facility

Currently there is a diversity of efficient industrial management techniques, some with a more traditional approach and others with a more modern and innovative attitude.

Modern techniques differ from traditional techniques because they leave a linear way of thinking behind, adopting a more dynamic and flexible way of understanding complex activities.

Of all the industrial management techniques, these are some of the most important:

5S Methodology

It is a technique of Japanese origin, consisting of a set of 5 stages based on oriental principles. Its name is due to the fact that the name of each of the 5 stages begins with the letter “S”.

The stages of the 5S method are:

Seiri: translated as sorting, this stage consists of identifying and differentiating between items that are necessary and those that are useless for production.

Seiton: this stage involves tidying, which basically consists of organising the industrial space, placing the items necessary for production in their proper place.

Seiso: linked to order and cleanliness in the industrial space.

Seiketsu: translated as standardisation, this stage involves preventing anomalies, i.e. disorder and dirt, by establishing appropriate standards and procedures for production.

Shitsuke: finally, discipline, a stage in which efforts to continue improving productive activity are encouraged.

Kaizen

This is another oriental technique, which stands out for its philosophy status. Kaizen is a word that means “improvement”.

Its main goal is to manage industrial quality through a continuous improvement process, consisting of simple and specific actions.

This technique considers the industry as a whole, in which every component (workers, managers, engineers, directors, etc.) has an active role in the search for continuous improvement.

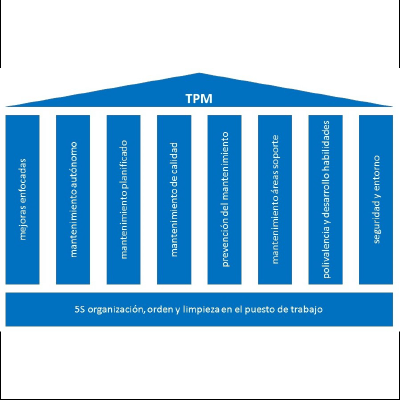

Total productive maintenance (TPM)

It’s a Japanese technique that has also risen to a philosophy status. It consists of the elimination of loss of time (stoppages, standstills, interruptions, etc.), quality and costs during production.

- Targeted improvements: a continuous improvement process that establishes the basis for making the necessary changes in a planned and precise manner.

- Autonomous maintenance: a set of activities carried out by machinery operators to preserve and condition the state of equipment and machines.

- Planned maintenance: systematic activities carried out to renovate the deteriorated state of machinery and equipment.

- Initial control: consists of learning from errors to reduce the deterioration of equipment and machines and lower maintenance costs.

- Quality maintenance: emphasis on compliance with quality regulations and standards.

- Training: process of training and preparing staff in their respective professional areas.

- Total productive maintenance in offices: refers to transferring the entire set of industrial improvements to office spaces.

- Safety and environment: consists of compliance with environmental and safety laws established by the government.

8D

This technique consists of eight disciplines, all of which are geared towards problem solving. It is particularly useful for dealing with issues in quality control.

The 8 disciplines of this method are:

- Formation of an expert team with knowledge in various fields

- Precise definition of the problem

- Apply and test a temporary solution

- Identify the root cause of the problem

- Determine and examine permanent corrective solutions

- Apply and verify permanent corrective solutions

- Prevent the recurrence of the problem and/or its causes

- Recognise the team’s efforts