In this article we will talk about the main finishes for concrete floors, their uses and characteristics.

But, first of all we tell you about what our company can provide you in relation to industrial flooring.

BECOSAN® as a finish for concrete floors

As a company specialized in polished concrete floors, in addition to offering you our own products to improve the quality of the floors, we have developed a unique system, which stands out for its effectiveness and efficiency.

Our core products for the treatment of concrete floors are:

- BECOSAN® Concrete Densifier is a concrete hardener that penetrates and reacts deep in the core of the concrete. It triggers a chemical reaction with the free lime in the concrete, modifying its molecular structure to make it stronger and harder.

- BECOSAN® Concrete Sealer is a sealer that creates waterproofing properties on concrete, minimizing the absorption of water, oil, grease and any liquid substance.

Our finishing system is based on the polishing of the concrete surface, which has been previously troweled or prepared for a BECOSAN® treatment.

At BECOSAN® we promote concrete polishing using our densifier and sealer, obtaining a finish with unique features that make it a multifuncional and durable flooring solution.

Contact us

What are the main finishes for concrete floors?

In general terms, 2 types of finishes for concrete floors exist and those are achieved depending on the operating mechanism used:

Polished concrete

This is, among many types of finishes for concrete floors, the most commonly used for interior flooring.

The final result of this finish is a shiny, smooth and uniform surface.

Polished concrete is a result that originates from a troweled concrete. The polishing process creates resistance on the surface, modifying directly the hardness of the concrete.

The final result of this finish is a shiny, smooth and uniform surface. For example, a salt and pepper polished concrete floor is achieved with a light grind that exposes fine aggregates for a speckled look while remaining smooth. Polished concrete is a result that originates from a troweled concrete floor. The polishing process creates resistance on the surface, modifying directly the hardness of the concrete.

We offer concrete polishing services in the UK and Europe.

10 years dust proof guarantee. Unique BECOSAN® patent

Smoothed concrete

It’s a simple finish. Smoothed concrete is the result of the process of uniformity driven by a vibration trowel, which generates the planimetry on the surface of fresh concrete, making its level balanced and its thickness homogeneous.

This finish is the basis for e.g. applying a coating.

Concrete floors with good finishes

It is necessary to be able to have concrete floors with good finishes. Without them, a whole series of problems would arise, such as those mentioned at the beginning of this article, such as abrasion wear and the generation of dust, weakening the structure of the floor.

Characteristics of a good finish

Texture:

This is a physical property resulting from troweling and polishing a concrete surface. A good finish represents a compact floor with a minimally rough surface texture.

Durability:

Concrete floors will be subjected to very different situations throughout their lifespan. For this reason they require a high resistance to abrasion wear caused by vehicles and people.

Planimetry:

The finish of a concrete floor must be uniform, continuous, regular and symmetrical. Uneven or rough floors complicate traffic and can cause risk of accidents.

Coatings for concrete floors

Finishes are not the only mechanism to ensure regularity to concrete floors. Coatings are the alternative. Currently there are several options, each with a series of benefits according to certain situations.

The most commonly used coatings today are as follows:

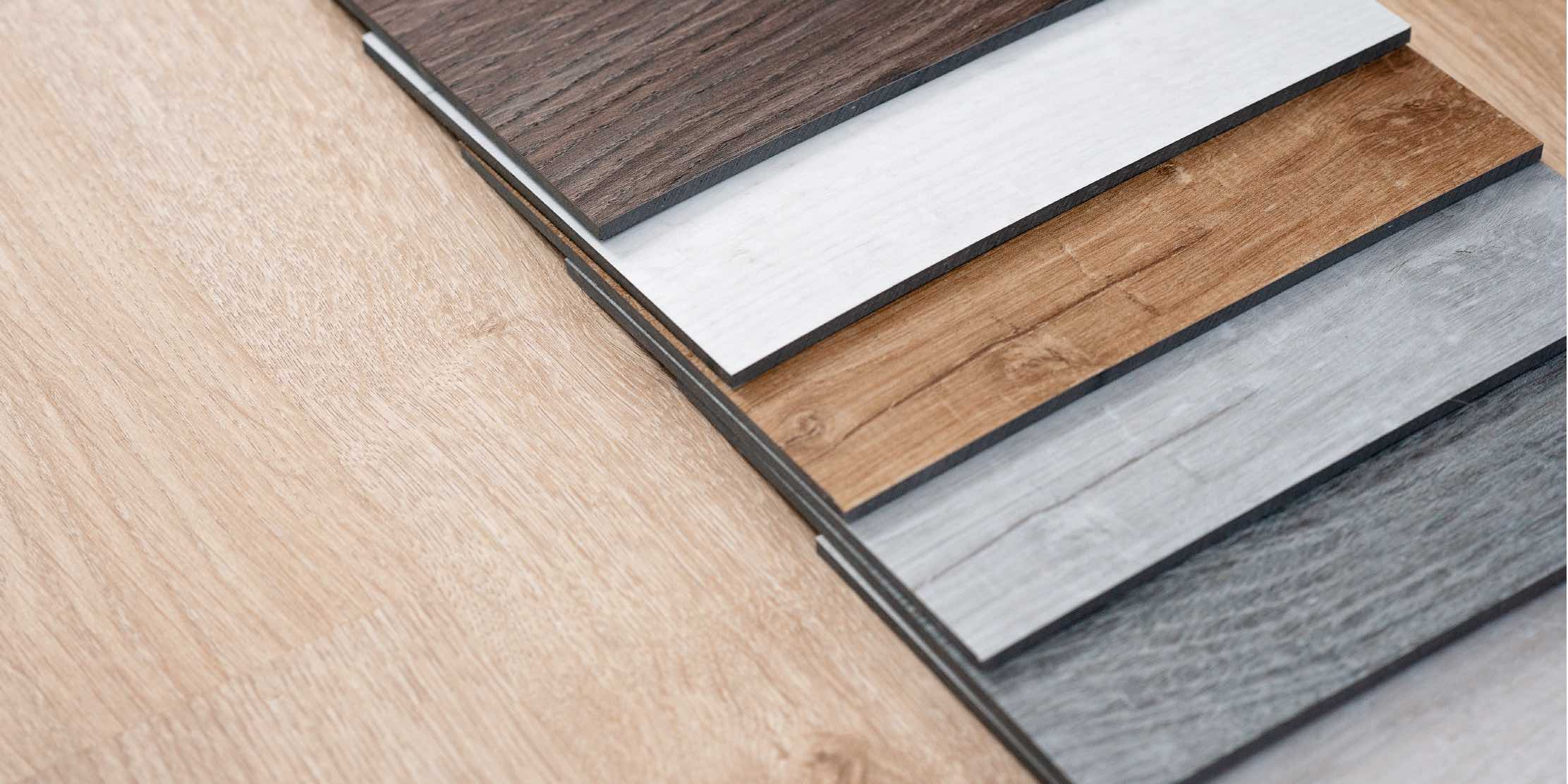

Vinyl floors

This coating for concrete floors consists of a plastic structure composed of PVC, i.e. polyvinyl chloride.

It is a continuous coating intended for buildings with low traffic and that have periodic cleaning.

It is known as the modern substitute for linoleum, as both are similar. However, vinyl stands out for being more durable and resistant, even has a greater tolerance to fire.

Vinyl floors are abrasion resistant, waterproof and easy to clean.

Linoleum floors

The material of linoleum floors is elaborated with linseed oil, which is mixed with wood flours and cork powder, and then solidified. These floors stand out for their remarkable flexibility and are resistant to high traffic.

Linoleum floors have an impressive water resistance. This makes them easy to clean and to maintain. In addition, they are one of the most affordable coatings on the market.

Composite floors

Composite is a coating resulting from the union of wood fibers and synthetic or plastic resins, usually polyvinyl chloride, or high or low density polyethylene.

This particular bond is subjected to a high pressure extrusion process, generating a cohesive structural state.

Composite floors stand out for their ecology and can be reused.

External floors are ideal for composite because they withstand most of the effects of weathering. Additionally, they are floors with high anti-slip capabilities.