Polished concrete floor contractors near me

We offer services all over the UK. Due to the nature of these jobs, we travel wherever you are. Among the main industrial areas where we provide services:

North West | North East | Yorkshire and the Humber | West Midlands | East Midlands | East Anglia | South West | South east | Greater London

Key points

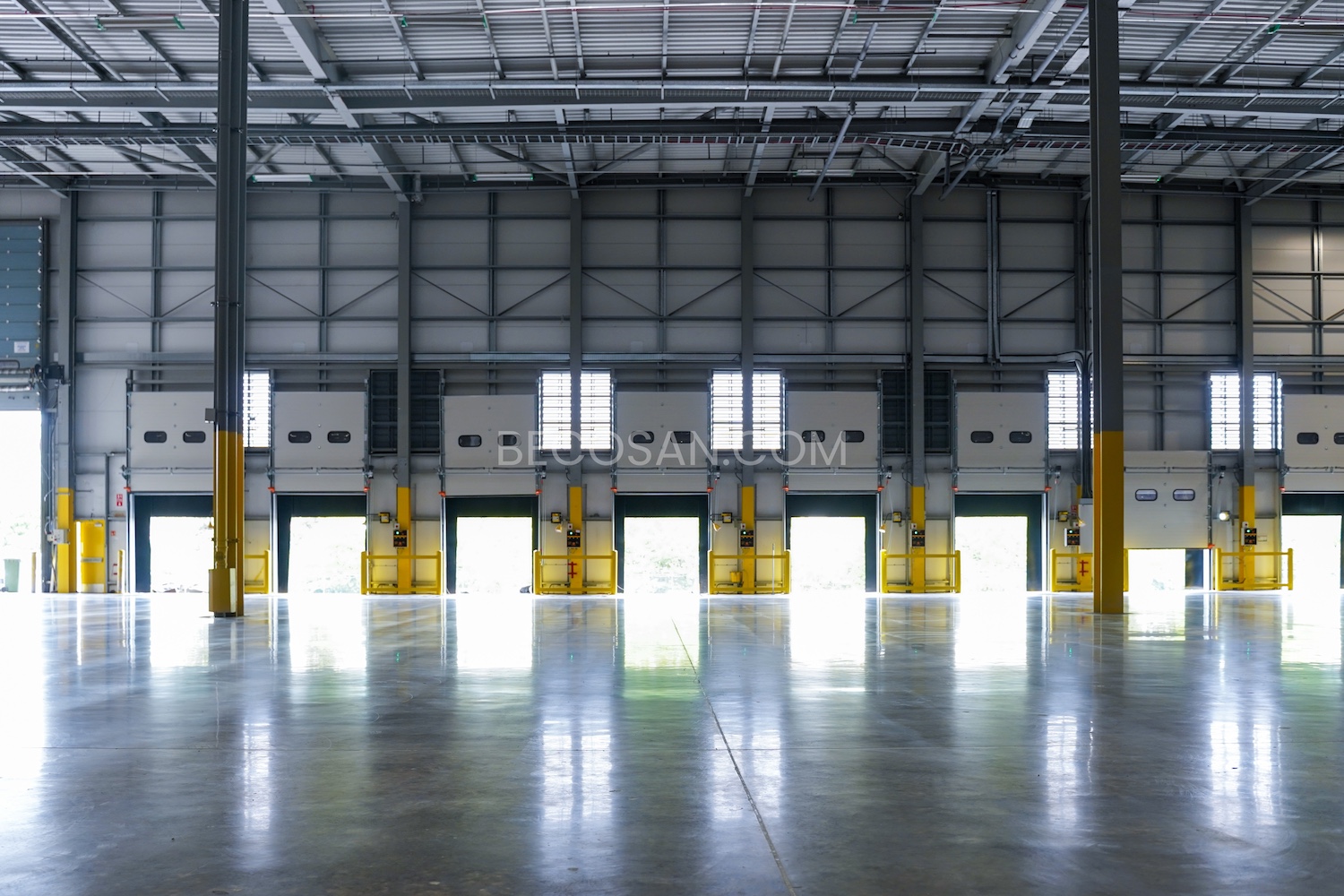

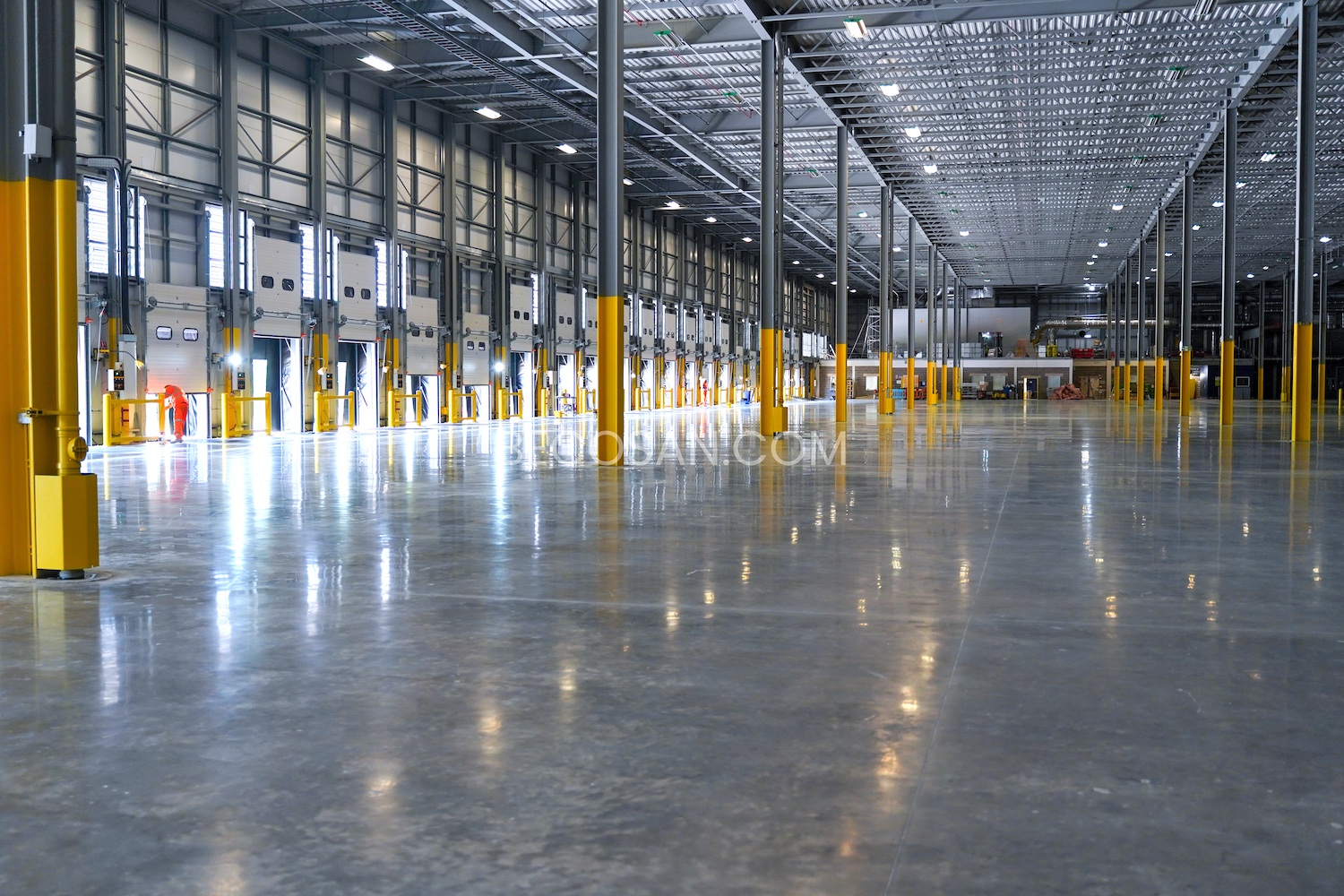

- Specialists in large surfaces

- Multifunctional floor finish

- Aligned with leed/breeam certifications

- Fast execution / Performance from 1.000 m2/day

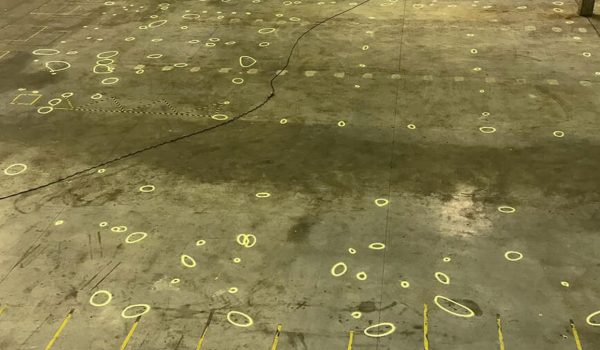

- For new or existing and deteriorated floors