Every company “should” be fully aware of the internal processes that allows finished products to be delivered to consumers. A supply chain includes all the operations and activities that enable a sales action to take place.

These processes have to be constantly supervised, from obtaining raw materials to manufacturing, distributing, transporting and delivering materials.

Basically, the purpose of a company that sells products is to make a profit by selling them.

What is a supply chain?

A supply chain (also known as the supply network) involves planning, organizing and controlling the activities related to the conception of a product until it reaches the end user.

6 Objectives of a supply chain

A supply chain aims to satisfy the needs of the end customer, in the best possible way. Therefore, a supply chain must meet the following objectives:

- Deal with any changes in supply, demand or environment.

- Establish adequate coordination and communication channels.

- Correct warehouse and inventory management.

- Improve distribution times.

- Provide products or services in a timely manner.

- Avoid losses or shortages.

“Another very important objective is to hire the right personnel to guarantee 100% operation and efficiency of the supply chain.”

3 Basic components of a supply chain

Supply chains have 3 fundamental components:

Supply

All activities dedicated to obtain and bring the necessary raw materials for manufacturing.

Production

Activities in which raw materials are transformed into a product or service.

Distribution

Taking the product or service to the final consumer by using a local, national or international transport network.

Who participates in a supply chain?

For a supply chain to have the necessary efficiency and normality, it must have the following protagonists.

Providers

People or companies that are in charge of distributing, providing or leasing the use of services and/or goods.

Transportation

It’s in charge of delivering consumables, finished products or raw materials to both companies and end clients.

Manufacturers

They transform raw materials into products or services.

Customers

They’re the most important part of a supply chain, as they are the ones to whom all processes are directed.

Communication

Another fundamental part as it guarantees all operations and members are coordinated properly.

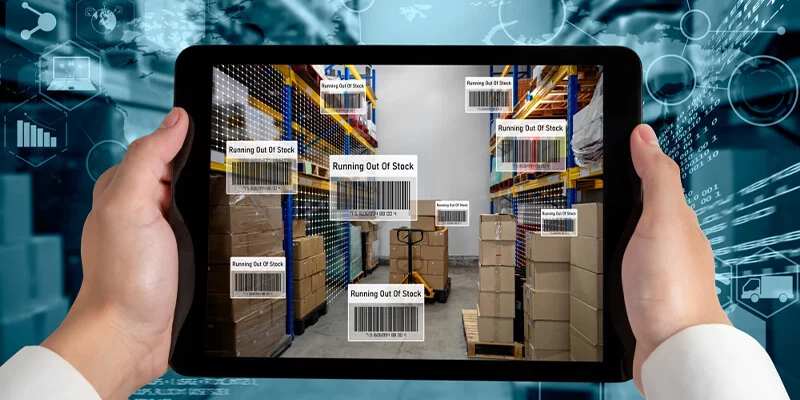

Technology

It allows the supply chain to optimize its tasks and get them done in the shortest time possible. In our opinion, and with the advances that are taking place in recent years using Industry 4.0 and industrial automation, we believe that technology is what really allows improvements to take place in all the phases of a supply chain.

“Technology allows us to provide accurate and real-time information on how all members of a supply chain act. This, in turn, enables agile and reliable decisions to be made.”

Artificial Intelligence in the supply chain

Investments in AI are becoming more and more important in all kinds of industries.

The benefits of AI in a supply chain are clear:

- Personalization for the end customer.

- Faster deliveries.

- Greater efficiency in operations.

- Risk reduction.

- Cost optimization.

Data management and a good AI system that seeks the constant optimization of processes and tasks is a great benefit. However, it’s a technology that is not an easily accessible product for all companies to assume.

What is an extended supply chain?

Extended supply chains are those that are not limited to the value provided by the company itself, but also involve various members of the chain to meet the needs of the end customer, from distributors to raw material suppliers.

Therefore, it includes all the parties that participate or interact one way or another in the elaboration of the product until it reaches the client (finances, information, etc.).

“An extended supply chain implies that sourcing, selling, manufacturing, transporting and delivery is a shared chain between the all the participants.”

For this to be a reality, the use of information and technology systems involving customers (and customers of customers), suppliers (and suppliers of suppliers) and distributors (and distributors of distributors) is essential.

This way, the supply chain of a company is optimized and benefits are achieved for all.

Activities within a supply chain

There are hundreds of thousands of companies in the world, but not one has the same supply chain as another. They are all different in activities and form.

However, there are always certain activities that are common to all:

Stock control

Determines the product stocks that the manufacturer has available for sale or transformation.

Merchandise distribution

Planning the delivery routes and transportation method: by land, sea or air.

Storage

Activities to keep products stored in a warehouse.

Customer service

All the resources and services that allow the product to reach the end customer. One of the tools that best allows this is a CRM (customer relationship management), because it allows us to know how distribution is going, stock status, marketing campaign results, as well as the collection and management of customer data.

Packaging

Processes aimed towards an adequate conservation and protection of the products.

Material handling

It encompasses all the mechanical and manual means that allow the product to be moved both within warehouses and at points of sale (forklifts, conveyors, belts, etc.).

Order processing

Activities that are associated to the managing purchase orders.

Types of supply chain

Depending on the type of company, we can distinguish different types of supply chains.

Trading companies

They receive and sell products, through customer requests, which they themselves manage.

Service companies

They depend a lot on human resources and have different hierarchical chains: management, production, commercial heads, distribution, etc.

Industrial business

They have a supply chain with spectacular logistics, which adapts to the size of the company, product lines and types of target audience.

Differences between a supply chain and logistics

We already know what a supply chain is, but: what is logistics? How does it relate to a supply chain?

As we have seen previously, a supply chain refers to the entire process that a product follows until it is sold.

However, logistics is integrated into the supply chain and includes all activities related to the storage of goods, as well as their transportation and distribution.

This way, a logistics chain is in charge of bringing the correct product, with the appropriate quality and cost, in the precise quantity, at the right time and at the correct destination. Of course, and as far as possible, within the indications agreed with the client.

Let’s use the example of a furniture store and divide it between supply chain and logistics chain.

Furniture store logistics chain

It focusses on acquiring different models and types of furniture to be exhibited in the premises, as well as those that customers have requested.

These are kept in the warehouse until distributed. The person in charge of the logistics will be in charge of designing the furniture distribution routes, coordinating between the assembly tasks and the delivery to the end customer.

Furniture store supply chain

However, the supply chain refers to all the previous stages that this final product goes through: extracting wood, transforming wood pieces and boards in the factory, and then the subsequent distribution to points of sale or customer’s homes.

Success stories of a supply chain

Now that you know everything about supply chains, we are going to mention two companies that carry out an adequate supply chain management.

Zara

It is the best example of efficient logistics. This is because it has excellent communication and coordination between the different links within its supply chain.

Clothing restock is always guaranteed and, in the event that something is out of stock, the client knows that they will have it in less than 2-3 days.

Walmart

Its innovative system allows products to be taken directly from the factory to trucks, saving on storage costs.

This allows you to offer customers products at a better price. Likewise, they use radio frequency tags that allow them to track merchandise instantly, avoiding losses and controlling the stock.

Conclusion

In this article, you have discovered everything you need to know about a supply chain.

“Now is the time to find out for yourself if your company has an appropriate supply chain to deliver products properly to your clients.”

Or, perhaps, you have also realized that your company has everything it needs to be able to expand its supply chain.

References

hese are some of the websites we have used for this article:

- mecalux.es

- fguell.com

- iltrasa.com.mx

- tradelog.com.ar

- economipedia.com