There are various types of security barriers available to suit different industrial requirements. Let’s explore some of the common types:

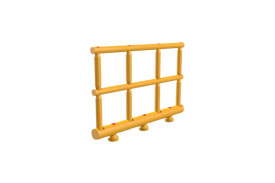

Safety barriers, also known as safety railing, are designed to create physical boundaries and prevent unauthorized access to restricted areas. They are typically used in areas where there is a risk of falls or where protection is needed against moving machinery or equipment.

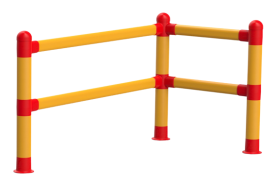

Forklift barriers safety focuses on protecting both pedestrians and infrastructure from forklift-related accidents.These barriers are high and are designed to create a safe distance between forklift traffic, pedestrians and working areas. By implementing forklift barriers safety measures, the risk of collisions and accidents involving forklifts can be significantly reduced.

Ground level barriers are commonly employed to segregate walkways from vehicular traffic or to prevent unauthorized entry into specific areas. Ground level barriers are typically installed at entrances, exits, or around sensitive equipment.

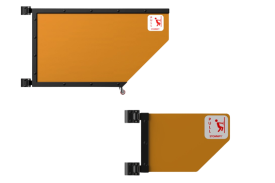

Industrial safety gates provide controlled access to specific areas while maintaining safety. These gates are often used to secure entrances to restricted zones. Industrial safety gates can be self-closing or manually operated, ensuring that access is only granted to authorized personnel.

Pedestrian safety barriers are designed to protect individuals walking in industrial settings. These barriers are often used in areas with moving vehicles or heavy machinery. Pedestrian safety barriers provide a clear separation between pedestrian zones and vehicular traffic, minimizing the risk of accidents and ensuring the safety of workers and visitors.

Safety barriers are crucial elements in industrial environments, providing protection for workers, infrastructure, and equipment. By implementing appropriate safety barriers, organizations can significantly reduce the risk of accidents and enhance overall safety.

If you are interested in learning more about safety barriers or need assistance in finding the right solutions for your needs, please reach out to us, and we’ll be glad to help.

Home » Industrial Protections » Safety barriers

In the industrial environment and in many workplaces, safety is a primary concern. It is essential to ensure the protection of workers, the segregation of risk areas and the prevention of accidents and property damage. An effective measure to achieve these objectives is the implementation of safety barriers.

In this section, we will explore the reasons behind the use of these protections and how they contribute to maintaining safe working environments.

Safety barriers are essential for segregating different areas within a facility, creating clear boundaries to prevent unauthorized access or accidental entry. By clearly defining specific zones, workers can be directed to designated areas, reducing the risk of accidents and ensuring a controlled workflow.

One of the primary reasons for implementing safety barriers is to safeguard the well-being of employees. In areas with potential hazards such as moving machinery, high-risk work zones, or elevated platforms, safety barriers provide a physical barrier to prevent accidental falls or unauthorized access.

Accidents can have severe consequences, both in terms of human injuries and financial losses. Safety barriers act as a proactive measure to prevent accidents from occurring in the first place. By strategically placing barriers in critical areas, such as walkways, staircases, or loading docks, the risk of collisions, falls, or other accidents can be significantly reduced.

When it comes to safety barriers, several important factors should be considered to ensure their effectiveness and reliability. These considerations include:

To ensure the highest level of safety, it is crucial to select safety barriers that meet industry standards and regulations. Look for barriers that are homologated or certified by relevant authorities, as this guarantees that they have undergone rigorous testing and comply with safety guidelines.

Safety barriers should be constructed using high-quality materials that can withstand demanding industrial environments. Look for barriers made from robust materials, that offer durability and resistance to impact.

Some safety barriers come equipped with additional safety features to enhance their effectiveness. These features may include self-closing mechanisms, locking systems, or warning signs for increased visibility.

Evaluating the available options and selecting barriers with these enhanced safety features can provide an added layer of protection and contribute to a safer working environment.