Reuse your existing slab with our industrial polishing system.

The eco-grind approach by BECOSAN® transforms new or existing concrete floors into hard, dust-free, and easy-to-maintain surfaces with a natural, satin-matte look.

Perfect for logistics centres, warehouses, and industrial plants across the UK.

Highlights

At BECOSAN®, eco-grind is not a product name but an approach — a responsible, low-impact, and highly efficient way to restore and polish industrial concrete floors.

Instead of covering the slab with synthetic coatings, we work directly on the existing concrete surface. Through a controlled grinding process, we remove micro-imperfections and open the pores to allow deep penetration of our lithium-based densifier. This chemical reaction hardens the surface from within, creating a denser and stronger concrete matrix.

Once densified and sealed, the floor no longer produces dust, even under heavy traffic. The process requires minimal maintenance — just neutral cleaning, no waxes or recoats — and significantly extends the lifespan of the floor. Compared to traditional epoxy or polyurethane coatings, the BECOSAN® eco-grind system achieves a lower environmental footprint while delivering superior long-term performance.

Creating a durable and natural polished concrete floor is not about adding layers on top — it’s about improving the concrete itself.

The BECOSAN® eco-grind process follows a series of carefully controlled steps that strengthen, seal and refine the surface to achieve long-term performance with minimal maintenance.

Below is a breakdown of how we turn existing or new concrete into a dense, dust-proof and easy-to-clean industrial floor.

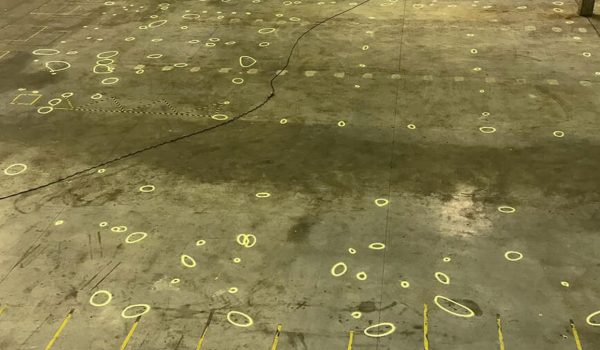

Old coatings, sealers, or paint are removed. Joints and cracks are repaired where necessary to prepare a consistent substrate.

Using industrial diamond grinders (walk-behind or ride-on machines), we gradually refine the surface to remove imperfections and micro-roughness.

A lithium-based densifier is applied, which reacts with the calcium hydroxide in concrete, creating a stronger, abrasion-resistant surface. This ensures the floor is harder, denser, and significantly more durable.

A breathable, non-film-forming protective sealer is applied to increase stain resistance while preserving the natural look of the concrete.

Depending on the specified finish (matt, semi-gloss, or high-gloss), we perform final polishing passes to achieve the desired sheen and smoothness.

The difference lies in both sustainability and performance.

BECOSAN® does not rely on synthetic coatings or film layers that peel or degrade over time.

We improve and reuse the existing concrete itself — no extra materials, no recurring recoats.

Because the surface is chemically densified and mechanically polished, it becomes harder, denser, and easier to clean.

Maintenance is simple: neutral detergent, water, and a scrubber-dryer. No waxing or repainting.

While epoxy or polyurethane floors may look similar when new, they require periodic re-application and can trap moisture or delaminate.

With BECOSAN®, you achieve a long-lasting, eco-friendly alternative that minimises downtime, reduces maintenance costs, and avoids unnecessary waste.

It’s a true eco-grind solution — sustainable by design.

Typical applications include:

Matt-PLUS / Semi-Gloss / High-Gloss.

Superior abrasion resistance and dust control.

Increased light reflectance can reduce energy consumption.

Up to 1,000 m² per day treated in phased programmes to keep your operation running.

We are a trusted, experienced company that adheres to all current legislation and industry regulations. Our commitment to quality and compliance ensures complete peace of mind for our clients.

BECOSAN® was proud to collaborate with Sunrise Real Estate Limited and Total Project Integration to deliver a massive 60,000m² (661,000 sq ft) natural polished concrete floor refurbishment project in Warwickshire, UK. The project involved dismantling, demolition, and eco grind concrete polishing at the former GAP warehouse, which was then leased to the retail giant Sainsbury’s. This was one of the most significant real estate transactions of the year.

SEGRO is a leading UK-based investment and property development company. We successfully completed a 16,000m² industrial floor rehabilitation project, delivering a high-quality natural polished concrete floor. This project highlights our expertise in eco grind concrete polishing and sustainable flooring solutions, ensuring long-term durability with minimal environmental impact.

Before deciding to transform your floor, it’s natural to have questions about how our polishing system works, what kind of results to expect, and whether it’s suitable for your specific environment.

Below we answer the most common queries about the eco-grind concrete polishing process and the natural polished concrete floors we deliver across the UK.

A basic “grind & seal” simply grinds the floor and applies a topical sealant.

BECOSAN® goes further — densifying, sealing, and mechanically polishing the surface itself for lasting strength and a 10-year dust-proof guarantee.

Yes. The BECOSAN® system is engineered for industrial environments with constant forklift or pallet-truck traffic.

Just neutral cleaning — no waxes, no coatings, no re-applications. The surface stays dust-free and easy to clean.

Depending on surface condition and project size, large-scale works can be executed in phases, often exceeding 1,000 m² per day, with minimal disruption.

No — it’s specifically designed for dry areas. For wet or permanently damp environments, other solutions should be considered.

Get a natural polished concrete floor that’s stronger, cleaner, and built to last.

Request a free technical survey or view UK case studies