BECOSAN® offers an eco grind concrete polishing system that transforms existing concrete floors into natural polished concrete floors that are highly durable, easy to maintain, and completely dust-free. Unlike traditional coatings or resins, our treatment enhances the inherent properties of concrete, creating a sustainable and environmentally friendly flooring solution for industrial, commercial, and warehouse spaces.

BECOSAN® is a mechanical-chemical polishing process that strengthens and seals concrete floors, extending their lifespan while maintaining a natural, high-performance finish.

Unlike epoxy coatings or synthetic overlays, the BECOSAN® system enhances the natural structure of concrete, making it a truly sustainable flooring solution without additional materials or harmful chemicals.

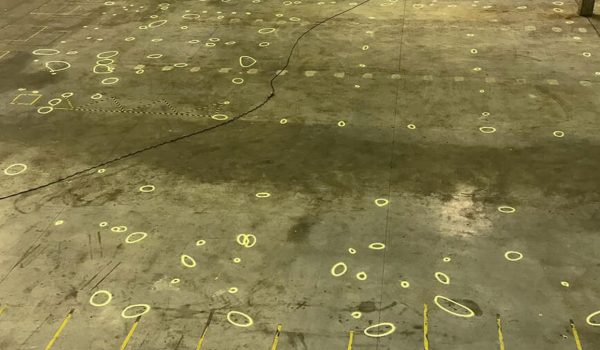

The process begins by smoothing out the concrete surface using industrial grinding equipment. This removes imperfections, opens the concrete pores, and prepares the floor for treatment.

The process begins by smoothing out the concrete surface using industrial grinding equipment. This removes imperfections, opens the concrete pores, and prepares the floor for treatment.

A lithium-based densifier is applied, which reacts with the calcium hydroxide in concrete, creating a stronger, abrasion-resistant surface. This ensures the floor is harder, denser, and significantly more durable.

Once the floor has hardened, we apply our water-based polymer sealer, which deeply penetrates the concrete rather than forming a surface film. This prevents liquid absorption, stains, and wear, creating a floor that is easier to clean and maintain.

The final stage involves polishing the surface to achieve a natural, aesthetically pleasing finish, tailored to the desired sheen level—matte, satin, or high-gloss. The result is a smooth, dust-free, and long-lasting floor with natural durability and eco-friendly benefits.

One of the biggest environmental advantages of BECOSAN® is its exceptional durability. While epoxy coatings or traditional floors require frequent replacements, a BECOSAN®-treated concrete floor can last decades with minimal maintenance. This longevity reduces material waste, carbon emissions from renovations, and the overall environmental footprint of your facility.

Both the BECOSAN® Densifier and Sealer are water-based and non-toxic, ensuring a safe, eco-friendly applicationthat does not release harmful residues. Unlike traditional hardeners or sealers, our solution fully integrates with the concrete, strengthening and protecting the floor without forming an artificial layer.

A polished BECOSAN® floor provides a high level of light reflection, improving overall brightness in industrial or commercial spaces. This reduces the need for artificial lighting, leading to lower energy consumption and improved workplace visibility, which supports sustainable building practices.

Traditional flooring solutions often rely on epoxy, polyurethane, or synthetic coatings, which require frequent replacements and emit volatile organic compounds (VOCs). BECOSAN® eliminates this issue by refining the existing concrete slab, reducing the need for additional materials and lowering the environmental impact. Our products are 100% VOC-free, contributing to cleaner indoor air quality and meeting international environmental standards like BREEAM and LEED.

Both the BECOSAN® Densifier and Sealer are water-based and non-toxic, ensuring a safe, eco-friendly applicationthat does not release harmful residues. Unlike traditional hardeners or sealers, our solution fully integrates with the concrete, strengthening and protecting the floor without forming an artificial layer.

We are a trusted, experienced company that adheres to all current legislation and industry regulations. Our commitment to quality and compliance ensures complete peace of mind for our clients.

BECOSAN® was proud to collaborate with Sunrise Real Estate Limited and Total Project Integration to deliver a massive 60,000m² (661,000 sq ft) natural polished concrete floor refurbishment project in Warwickshire, UK. The project involved dismantling, demolition, and eco grind concrete polishing at the former GAP warehouse, which was then leased to the retail giant Sainsbury’s. This was one of the most significant real estate transactions of the year.

SEGRO is a leading UK-based investment and property development company. We successfully completed a 16,000m² industrial floor rehabilitation project, delivering a high-quality natural polished concrete floor. This project highlights our expertise in eco grind concrete polishing and sustainable flooring solutions, ensuring long-term durability with minimal environmental impact.

Tell us about your floor. One of our specialists will get in touch to evaluate your needs and provide a no-obligation quotation.