Wax coatings are often seen as a quick fix to improve the appearance of a concrete floor. They add shine, improve cleanability, and are relatively inexpensive. But when durability, safety and performance really matter — especially in industrial environments — wax may not be the best answer.

Concrete wax, or wax concrete, is a finishing product applied to the surface of a concrete floor to enhance appearance and aid maintenance. It’s typically made of water-based acrylic copolymers and designed for areas with light to moderate foot traffic.

In domestic settings, it can be a reasonable choice. For commercial areas with slightly higher wear, solvent-based waxes are often recommended for improved resistance to black heel marks and scuffs. These waxes, when maintained properly, also provide some slip resistance.

However, in industrial environments — where the floor is subject to heavy machinery, intensive use and stricter safety standards — wax is not a recommended solution. It simply lacks the durability and resistance needed in such demanding settings.

Although a waxed concrete floor may resemble polished concrete visually, they are fundamentally different. Wax is a superficial film; polished concrete, like BECOSAN®, is a mechanical transformation of the actual floor surface.

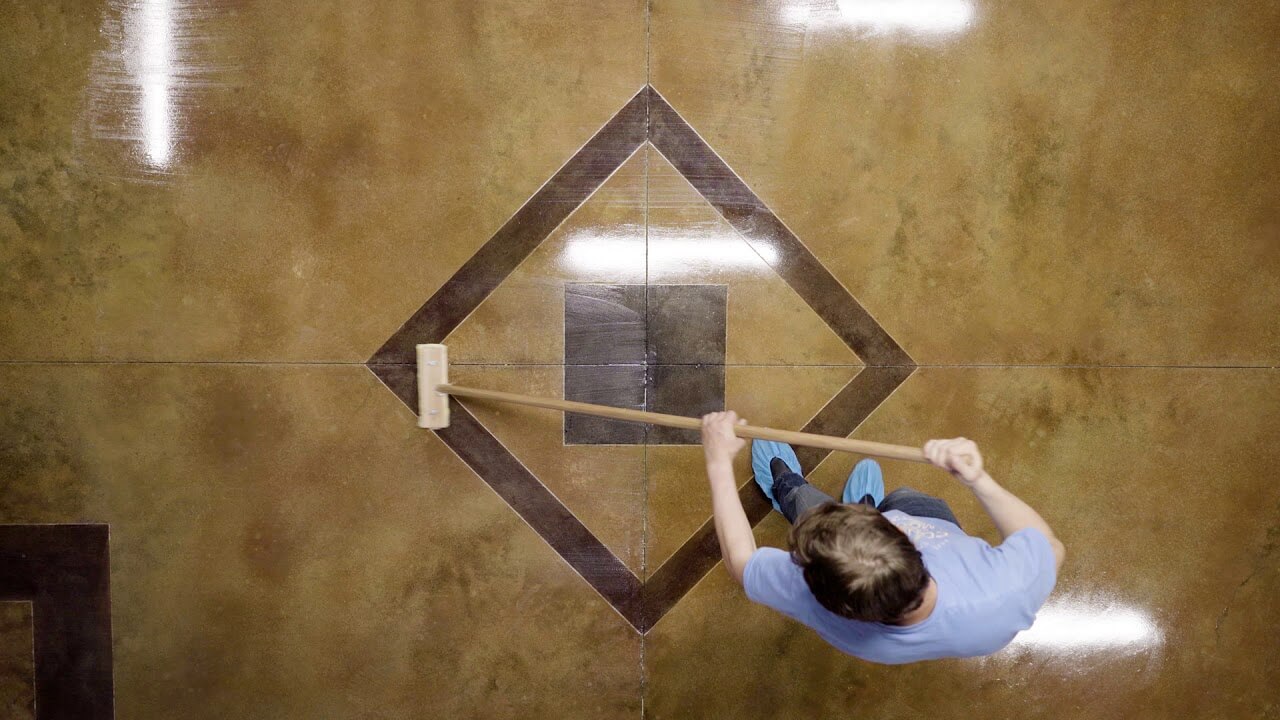

Most acrylic-based concrete waxes are mop-down products applied using a microfiber mop. Cotton mops are discouraged, as they tend to leave streaks and lint.

Solvent-based waxes, used in more demanding environments, are typically applied with heavy-duty floor buffing machines. The process is simple, but the results are short-lived unless constantly maintained.

The durability of a waxed floor depends on the quality of the product and the level of use. In low-traffic areas, wax can last for a while. In high-traffic zones, it wears quickly.

To maintain protection, multiple layers are often applied — sometimes up to 10 coats in busy spaces. Even then, over time, the wax degrades. If not reapplied regularly, the finish fades, and the floor becomes exposed and harder to maintain.

At first glance, applying a wax coating might seem like a quick and easy way to enhance a concrete floor. It gives a nice shine, improves cleanability, and is commonly used in shops or homes.

But in industrial environments, things are different. Heavy traffic, machinery, and long operating hours place much higher demands on the floor — and wax simply can’t keep up.

Wax coatings degrade quickly when exposed to constant use. Forklifts, pallet jacks, and foot traffic wear them down fast, leading to patchy, dull surfaces. Worse, if maintenance isn’t done regularly, wax can become dangerously slippery.

That maintenance isn’t minor, either. Floors need to be stripped and re-waxed often, causing interruptions and long-term costs. And despite all this effort, wax doesn’t actually improve the concrete itself — it just covers it.

BECOSAN® offers a completely different approach. Instead of applying a layer that will eventually fail, we treat the concrete itself — mechanically, permanently, and professionally.

Our mechanical polishing system refines the surface of the concrete slab, making it dense, smooth and dust-free.

Through densification and sealing, we harden the surface and close the pores, reducing wear and making cleaning easier.

Once treated, the floor requires no wax, no coatings, and no ongoing layers.

Our system is designed for the needs of logistics centres, warehouses, production areas and retail floors with high traffic.

An improvement

Removing wax from a concrete floor becomes necessary when the coating begins to wear, lose its appearance or prevent further improvements. Whether the goal is to prepare the surface for a professional treatment or simply to stop relying on temporary fixes, here’s how the removal process works.

To remove wax effectively, 3–4 litres of hot water are mixed with 2 cups of commercial wax stripper in a plastic bucket. The solution is applied generously to the floor using a mop or soft-bristle brush.

It should rest for 5 to 10 minutes, with more product added if the surface starts to dry out. Once the wax softens, the area is rinsed thoroughly using warm water and a clean mop.

Vinegar may help remove older layers of wax in some domestic cases, but its effectiveness on concrete floors is limited. For large or treated surfaces, a commercial wax remover is far more reliable.

While isopropyl alcohol (IPA) is sometimes suggested as a wax cleaner, a degreaser is usually more effective, since wax is an oily substance. IPA has mild degreasing capabilities, but in most cases, a dedicated degreaser ensures better results in less time.

Tell us about your floor. One of our specialists will get in touch to evaluate your needs and provide a no-obligation quotation.