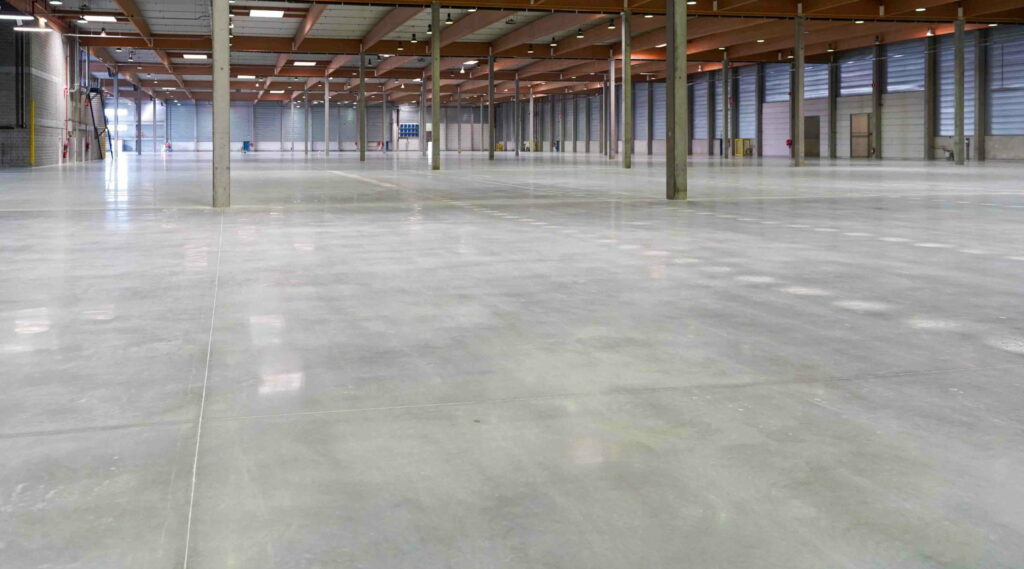

Epoxy flooring is often presented to warehouse operators, manufacturers and logistics centres as a long term solution that combines mechanical resistance, easy cleaning and a neat visual appearance. On paper it can look close to permanent.

In reality, the question most decision makers care about is simple: how many years will an epoxy floor actually last in a building before serious work is needed. There is no single number that applies everywhere, but there are realistic ranges and very clear factors that shorten or extend the lifespan.

Theoretical lifespan versus real world performance

Technical data sheets and sales presentations often talk about five, ten years or more. These figures assume ideal conditions that rarely exist in busy industrial facilities.

In real life, the following ranges are far more honest and useful as a starting point:

- 3 to 5 years in busy logistics warehouses with narrow aisles, intense forklift traffic and constant turning and braking.

- 2 to 4 years in chemical, food or other aggressive environments with frequent spillages, heavy cleaning and thermal shock.

- 5 to 8 years in lightly used areas with moderate traffic and a good maintenance plan.

After these periods the floor does not disappear, but visible defects start to accumulate. The surface begins to lose gloss and colour, abrasion marks appear in traffic lanes and local delamination, blisters and cracks reflecting through the coating become more frequent. At some point, the cost and frequency of repairs mean that a full reapplication of the epoxy system is needed, not just another patch.

What really determines how long an epoxy floor lasts

The lifespan of an epoxy floor does not depend only on the brand of the product. It depends on the whole system and on how the surface is used every day.

Substrate quality and system design

Two facilities can use the same epoxy product and get completely different results. Some of the key variables are:

- Strength and quality of the concrete slab.

- Presence or absence of a vapour barrier under the slab.

- Type and quality of the primer.

- Real thickness of the system in millimetres, because a thin decorative film does not perform like a multilayer or epoxy screed.

If the system is applied on a slab with too much moisture, poor mechanical preparation or badly treated joints, the epoxy will start to fail early. In those cases blisters, detached areas and cracking appear much sooner than expected.

Traffic intensity and type of use

A floor in a light assembly area is not comparable with a high throughput logistics hub. Epoxy floors suffer most in facilities where forklifts run all day in the same lanes, where there are constant accelerations, braking and tight turns, and where pallets, metal containers or equipment are dragged rather than lifted. In these situations the abrasion and impact shorten the time before the coating loses thickness and protective capacity. What was theoretically ten years can become three to five years in a real warehouse.

Chemical and thermal exposure

Many clients choose epoxy because of its chemical resistance, but that resistance has limits. Aggressive detergents and disinfectants slowly attack the surface over time. Hot oils, fats, acids and alkalis can stain, soften or damage the coating. High process temperatures and thermal shock from very hot or very cold washdowns place repeated stress on the resin. In aggressive zones it is common for the reapplication cycle to drop to only a few years, even when premium systems are used.

Maintenance and intermediate repairs

An appropriate cleaning regime and quick repairs help, but they do not reset the clock. Local patches and touch ups rarely restore the system to its original performance. When new coats are applied on top of old ones, the total thickness increases and small transitions and edges appear between layers. Each extra layer introduces additional interfaces inside the system, and each interface is a potential weak point. Good maintenance can stretch the lifespan a little, but it cannot turn a three to five year floor into a fifteen year solution under heavy use.

When repainting stops being a sensible option

There comes a moment where an epoxy floor has seen so many repairs and extra layers that repainting again is no longer a rational strategy. The total build up becomes hard to manage, with steps at joints and a noticeable loss of flatness. Some of the older layers below have poor adhesion, so the visible top coat is only as strong as the weakest interface. Each new intervention requires clearing areas, protecting equipment and stopping production or logistics activities, which increases the indirect cost of every project.

When the floor has already gone through several repaint cycles, the question changes. It is no longer about how many more years this epoxy will last, but whether it still makes sense to rely on a coating that will have to be replaced again. For many sites this is the point where they start to look for an alternative to epoxy flooring that works with the concrete itself instead of adding another organic layer.

The real cost

When calculating the total cost of an epoxy floor over its life, the material is only one part. You also have to consider the initial supply and installation cost, the cost of each major repair or full reapplication and the internal time and resources required to empty zones, move stock, protect machinery and clean. Above all, you have to factor in the cost of downtime when aisles or production areas are out of service.

In a calm warehouse that is used mainly for storage, a recoat every five to eight years may be acceptable. In a high performance logistics centre or a production line where every hour of stoppage has a clear cost, repainting every three to five years becomes a strategic problem, not just a technical one.

Using the concrete as the final surface

One way to escape from repeated epoxy cycles is to stop depending on a coating that is designed to be replaced. Instead of adding an organic film on top of the slab, the concrete itself becomes the final industrial surface.

This approach is based on mechanical grinding and controlled refinement of the surface, combined with chemical densification that increases surface hardness and reduces dusting and absorption. Finishing steps can deliver different levels of gloss while keeping the mineral character of the floor. On new slabs the most robust strategy is to design a good concrete floor from the start, sometimes with a mineral wearing layer such as a dry shake finish, and then to optimise and protect that surface with a durable mechanical and chemical treatment. This type of system fits naturally within modern ndustrial flooring solutions that focus on long term performance rather than recurrent replacement.

In this model the floor no longer depends on the lifespan of a resin. It depends on the intrinsic durability of the concreteand on relatively simple maintenance tasks.

What do the years look like in comparison?

To give a clear picture:

- For most industrial facilities, an epoxy floor should be planned in cycles of about 3 to 7 years, depending on traffic, exposure and maintenance. In the hardest conditions the realistic figure is closer to 3 to 5 years.

- A densified and polished concrete floor does not follow the same cycle logic. The slab remains in place and the surface is maintained and locally improved over time, without full removal and replacement of a coating every few years.

Many operators who have moved from epoxy systems to concrete based solutions report that the floor stops being a recurring project and becomes a long term asset with more predictable and usually lower maintenance costs.

Conclusion

When we talk about the lifespan of an epoxy floor it is possible to give realistic figures. Under heavy industrial use you should expect 3 to 5 years before significant work, and under moderate use about 5 to 8 years.

The more important decision, however, is the model of floor you choose. An organic coating will always have a limited lifespan and will require periodic reapplication. A concrete based system treats the slab as the final surface and reduces the dependence on layers that wear, yellow or peel.

If your installation is already on its third or fourth epoxy cycle, the key question is probably no longer how many more years this coating will last. The real question is what alternative you have to get out of this cycle and design a floor that supports your operation in the long term, with fewer stoppages and a more controlled total cost.

Carlos Ruiz

This article has been reviewed by Carlos Ruiz, General Project Coordinator for the UK at BECOSAN® UK LTD, to ensure technical accuracy, up-to-date information, and alignment with industry best practices.