In this post we will talk about the top 8 reasons why an epoxy resin floor can start to give you problems in different ways, as well as the mishaps resulting from these situations.

1. Poor surface preparation.

The bond between the new epoxy and the existing floor is critical. The existing surface must be roughened in order for the epoxy to adhere properly.

To make the surface ready for epoxy installation, we suggest diamond or metal grinding the floor to remove all possible flaws.

The installation surface must be clean, dry and completely dust free. Otherwise, your new floor will adhere to contaminants on the floor.

What problem can this cause? Total or partial lack of adherence (“peeling”).

The causes of this lack of adhesion can be due to:

- The resin was applied on a surface that does not ensure adhesion.

- Bad preparation of the surface: Excess of humidity, it was very dirty, etc.

Another problem that can cause: Lumps or sticking on the applied surface.

We have again as problem, to the bad cleaning and preparation of the base or the incorrect use of the equipment when applying the resin.

2. Excess of humidity

The solvent-based epoxy resins do not bond well to damp or directly wet substrates, hence in the previous section we have stressed the importance of the surface being completely dry.

However, even if the pavement is dry, we cannot avoid the existence of a little residual humidity of the support or that there is no rising damp.

The severity of damage to the epoxy floor will depend on several factors:

Water accumulation in the subfloor.

Breakage of water pipes underneath the flooring.

What problem can occur? A surface with greasy stains, loss of gloss and color changes (“Amine blush”)

This is caused by condensation, high humidity or that the resin was in contact with water during curing/drying.

This results in waxy, greasy or sticky surfaces. Grayish or whitish staining or direct loss of gloss may also occur.

3. Weak substrate.

This can mean several things:

- The pavement has already fulfilled its useful life

- A bad mix of ingredients (excess water or low cement content).

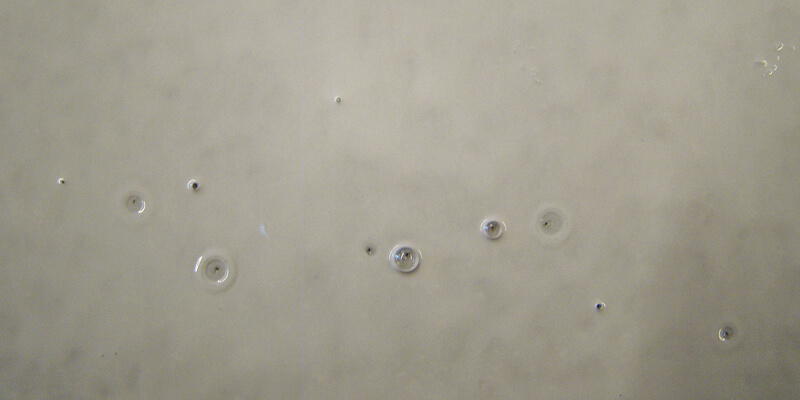

What problem can it cause? The formation of pinholes or craters

Pinholes are known as outgassing and occur when epoxy resin is applied to porous surfaces, such as concrete.

The air is trapped in the pores of the concrete after curing and when it wants to escape it presses on the resin layer, creating these blisters or craters.

4. No primer or an incorrect primer.

After preparing the surface, apply the appropriate primer and wait for it to dry to ensure proper bonding between the substrate and the epoxy.

Therefore, as soon as the primer has dried, there is no time to waste in installing the flooring.

Commercial and industrial flooring experience a lot of usage and it’s essential to ensure that the correct primer is chosen to meet the specific needs and requirements of your substrate.

5. Incompatible or inappropriate substrate.

Epoxy floors are tough, but cannot compensate for an unsuitable substrate, such as wood. Wood is never a suitable surface for an epoxy installation.

Plywood flooring is too flexible for epoxy, and the expansion and contraction that it undergoes during variations in temperature and humidity are too great for an epoxy to successfully resist.

This leads to tearing, peeling, cracking, and in the end, to failure.

Ultimately, it is essential to ensure that the surface will be compatible with the epoxy resin.

Likewise, the adhesion capacity and tensile strength of a surface are also important aspects to evaluate before starting the installation.

What problem can this cause? A sticky or soft surface (“tacking”)

It appears after the necessary curing time has elapsed and we see that the resin not only has not cured properly, but it is completely fresh or soft.

It may be due to the environmental conditions or the surface to be paved not being suitable.

Other problem that can cause: Sagging (vertical applications)

This problem is unique to vertical applications of epoxy resins. It occurs when too much resin is applied and also due to very high temperatures.

6. Reconditioning contaminated floors.

These problems are very common in installations with old pavements that need to be renovated. Industrial activities have been carried out on these substrates that have absorbed contaminants such as grease, oil or other residues, which cause poor anchoring of the pavement or detachment of the coating.

We are talking about food and beverage factories, car repair shops, industrial chemical plants, etc.

In cases such as these, special preparation must be done to ensure that any contaminants that could cause the epoxy to fail are removed or completely removed before the new floor is installed.

However, if the level of “contamination” is already very high, it is difficult to fix.

All oils, grease and debris should be thoroughly cleaned up before installing the new epoxy.

7. Faulty resin mixing

If the floor is very sticky after a long time or the curing has not been done well, it may be because the mixing time was insufficient or the components were not in the right proportion.

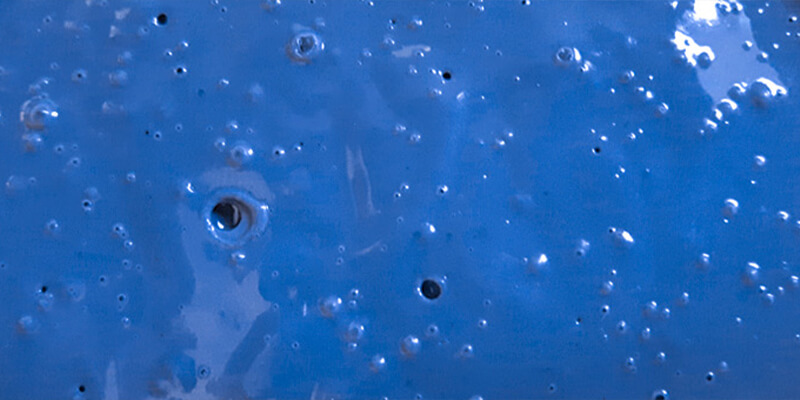

What problem can this cause? Air bubble formation

Occurs when air is trapped within the mixture due to too rapid agitation of the mixture and bubbles form on the surface after curing. The problem is aggravated when applied at very low temperatures, since the product is more viscous and makes it more difficult for air to escape.

8. Using the pavement ahead of schedule

Sometimes, the urge to get back to business does not work in our favor. If we expect to be back to normal within hours, nothing could be further from the truth. You may have to wait up to a week for the epoxy to cure chemically and even ensure proper adhesion to the surface.

If you want to avoid future problems with the epoxy, it is recommended that you respect the drying time of the epoxy.

WARNING: We are not saying that you can’t even walk on it. Rather, we are referring to not doing intensive cleaning, avoiding contact with water or using heavy machinery or transportation.

CONCLUSION

The epoxy is a type of pavement present in many industrial buildings, warehouses, logistics centers and industries in general, but that generates too many problems. And that unfortunately does not last as long as you would like and requires re-applications over time.

However, there is an alternative, which we show you in the following article: Alternatives to epoxy.

Anyway, if you are sure you want to repair your epoxy floor, read this other article: How to repair an epoxy floor?

And if you want to know where the price range of these repairs goes, we have also created this article: How much does it cost to fix an epoxy floor?

Case study: From epoxy to polished concrete

We recovered an epoxy floor with problems and in poor condition and transformed it into a beautiful polished concrete finish that offers greater safety and resistance.