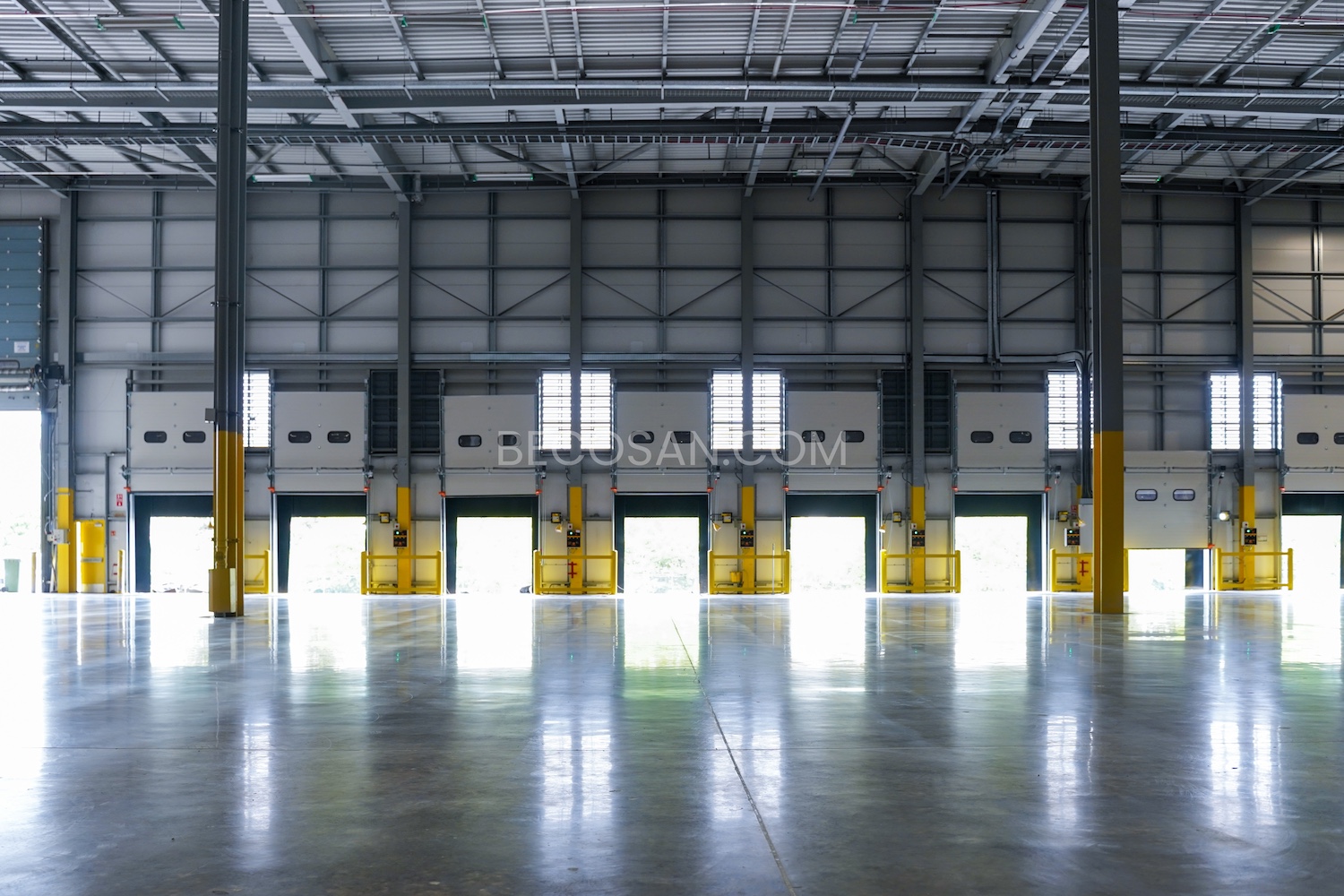

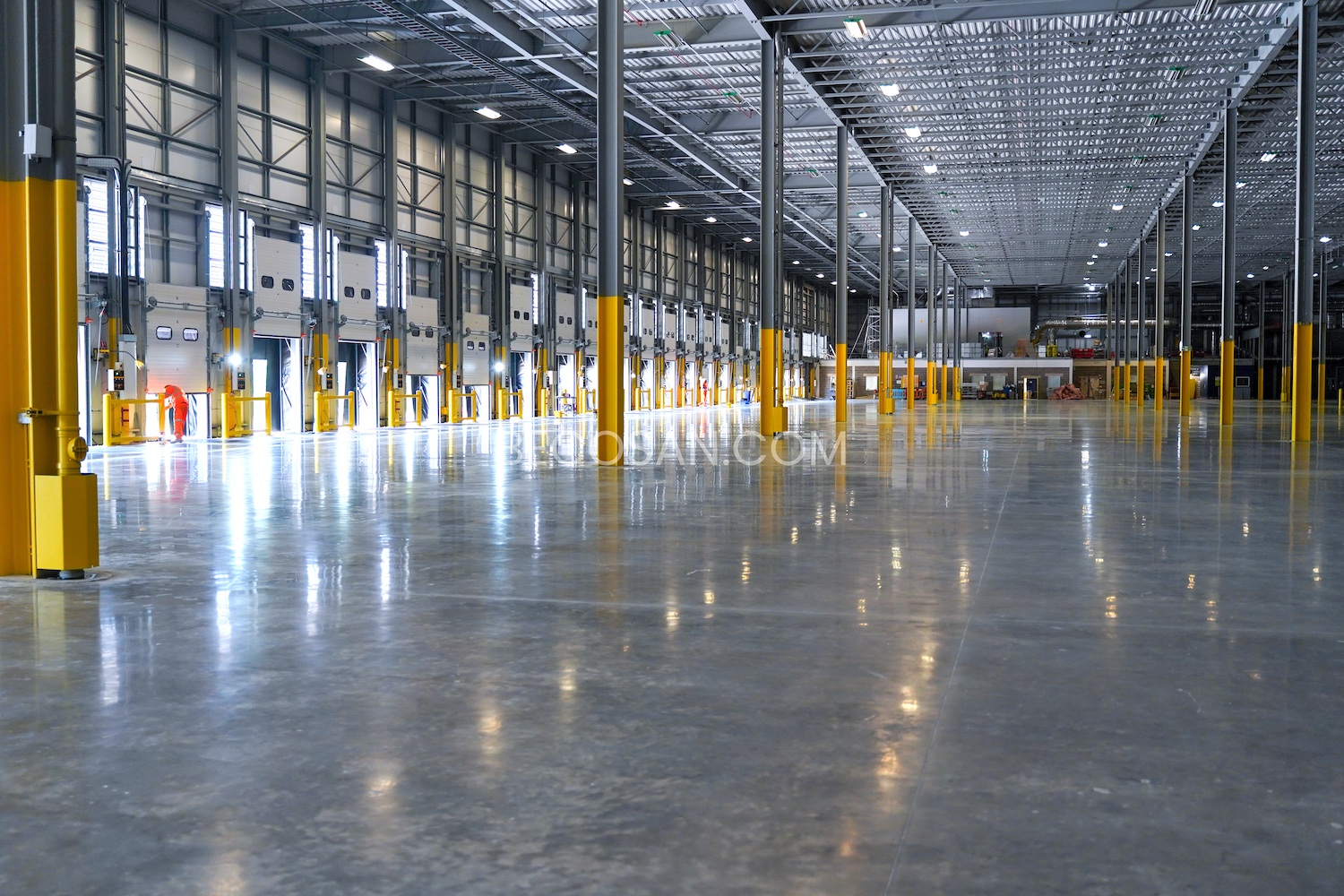

BECOSAN® Solutions

Alternative to epoxy flooring

Epoxy floors are a common solution for industrial and commercial surfaces, but they are not always the most reliable or cost-effective option. If you are looking for an alternative to epoxy flooring that provides greater durability, easier maintenance, and long-term performance, BECOSAN® polished concrete offers a proven system that meets the highest industrial standards.